Words in italics indicate a cross-reference.

ACCOUTREMENT: Also known as Accouterment. A generic term given to those items of equipment, other than clothing and weapons, issued to military personnel. Accoutrements differed between each branch of the armed services. Examples of artillery accoutrements include the waist belt, short sword, artillery saber, fuze pouch, pistol, holster, cap box, and gunner’s haversack.

AMMUNITION: Sometimes this name is given to cannon and mortars, as well as to the projectiles and explosive substances employed with them; but more usually ammunition is considered to apply to the latter – such as shot, shell gunpowder, cartridges, fuzes, wads, grenades. Muskets, swords, bayonets, and other small-arms are sometimes, but improperly, included under this term. The Royal Laboratory at Woolwich is the place where ammunition is chiefly prepared for the British army and navy. The cannon-balls may be cast at some of the great iron foundries in the North; the shells may be cast or forged in the shell-factory at Woolwich; the muskets may be made at Birmingham, and the rifles at Enfield; the bullets at the shot-factories; the gunpowder at Waltham Abbey – and so on; but the "making up" of the ammunition is mostly conducted at the establishment above mentioned. In the United States, ammunition is prepared at the various Arsenals and by numerous private Manufacturing Companies. Bags of serge, in enormous number are cut out and made, and filled to form the cartridges for large ordnance. Bags or tubes of paper are made and filled to constitute blank cartridges for small-arms; while the ball-cartridges are enclosed in thin copper cylinders. The tubes and combustibles for war-rockets and fuzes are also manufactured. The cartridges for small-arms (rifles, muskets, carbines, and pistols) are made in millions; since it is on those that the main offensive operations of an army depend. It has been calculated by the Woolwich authorities that a British army of 60,000 men, comprising a fair average of infantry, cavalry, artillery, and engineers, ought to be provided with no less than 18,000,000 ball-cartridges for small-arms, for six months’ operations. These would require 1000 ammunition-wagons and 3600 horses to convey them all at once. It is therefore deemed better that, under any such circumstances, there should be established entrepots for supplying the troops from time to time. The wagons constructed for this kind of service will carry 20,000 rounds of small-arm ammunition each; the cartridges are packed in boxes, and the wagons are drawn by four horses each. Several wagons are organized into an "equipment," under the charge of a detachment of artillery; and there are several such equipments for an army of the magnitude above mentioned – one for each division of infantry, a small portion for the cavalry, and the rest in reserve. It has been laid down that an army of 60,000 men ought to have 2,680,000 cartridges with them, besides those in reserve; and that the conveyance of such a quantity, with a few forges and stores, would require 150 ammunition-wagons, 830 men, and 704 horses. The equipment would return to the entrepot for a new supply when needed. In the Peninsular War, and at Waterloo, the English used two-horse carts, carrying about 10,000 rounds of small-arm ammunition each; but a superior kind of wagon has been since introduced. In the field, an infantry soldier usually carries about 60 rounds, put in compartments in his pouch. When the word ammunition is used in connection with artillery matters, the "fixed" ammunition comprises the loaded shells, cartridges, and carcasses; whereas the "unfixed" are the unfilled case-shot, grape-shot, and shell. Curing peace, the Woolwich laboratory serves out little less than 1,000,000 pounds. Of gunpowder annually, in ammunition for the army and navy, for the purposes of exercising, saluting, etc. The chief kinds of ammunition will be found briefly described under their proper headings. See Ammunition-boxes, Breaking up Ammunition, Cartridge, Center-fire Metallic-case Cartridge, Field and Mountain Ammunition, Fixed Ammunition, Metallic Ammunition for Small-arms, Paper Ammunition for Small-arms, Preservation of Ammunition and Fireworks, Siege and Garrison Ammunition, Stand of Ammunition, and Strapped Ammunition.

AMMUNITION-BOXES: Packing-boxes for field ammunition are made of well-seasoned stuff (generally white pine), 1.25 inch thick, dovetailed with the tenon on the ends. The top of the box is fastened with six 2-inch screws; the box has two handles of 1 ¾ inch rope, attached to brackets at the ends. The boxes are painted on the outside different colors to indicate the contents of the box. Those containing shot are painted olive; shells, black; spherical case-shot, red; and canisters, a light drab. The kind of ammunition is marked on each end in large white letters. The place and date of fabrication are marked on the inside of the cover. The boxes are packed as follows:

For Smooth-Bore Guns. – Shot, spherical case and canisters, fixed. – Laid in two tiers across the box, the shot or canisters alternating with the cartridges at each side. The shot or canisters of the upper tier rest on those of the lower and not on the cartridges. Canisters are packed in the same manner, omitting the strips of wood in the bottom of the box.

For 12-pounder Mountain-Howitzer. – Shells and case-shot, fixed. – Placed upright, the balls down, resting on strips of wood as for the other howitzer. Canisters are packed in the same manner, resting on the bottom of the box.

For Rifled Funs. – Shells and case-shot. – Placed upright, the balls down, resting on strips of wood as for the howitzer. The iron part of the balls rest against strips of wood 4 inches wide and .25 inch thick, nailed to the side and ends of the box at the bottom, and similar strips placed between the rows of the balls to prevent the soft metal cups from bearing against the box or against each other and being bruised; the cartridges are placed on top of the projectiles. Canisters are packed in the same manner as the case-shot, omitting the strips of wood on the bottom of the box.

In all the boxes the small stores are placed in the vacant spaces on top of the ammunition. A layer of tow is placed in the bottom of each box, and the whole contents are well packed in tow, filling the box so as to be pressed down by the cover. About three pounds of tow are required for a box. See Ammunition and Madigan Ammunition-box.

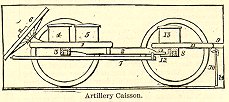

AMMUNITION CHEST(S): Wooden chests used to store ammunition for use in the field. When being transported, the chests were attached to the artillery limber and served as a seat for the cannoneers. Large metal handles on each end served to lift the chest and as a hand support for the cannoneers seated on the chest. The weight of an empty chest was 185 pounds, a fully-loaded chest could weigh as much as 560 pounds depending upon the type of ammunition. Limbers could hold one chest and caissons usually held two. Chests are placed on field-limbers and caissons for the transportation and safe-keeping of the ammunition. The limber has one and the caisson has three such chests, which will seat twelve cannoneers if necessary. The interior compartments of the ammunition-chests vary according to the nature of the ammunition with which they are loaded.

AMMUNITION CRATE: Also known as a packing box. Crates were made of wood with rope handles and were stenciled on the outside to indicate the contents. Those containing shot were painted olive; shell, black; spherical case-shot, red; and canister, a light drab. The kind of ammunition was marked on each end in large white letters. The place and date of manufacture were marked on the inside of the cover.

AMMUNITION-WAGON: A carriage employed for the transportation of ammunition. The points essential in the general construction of field-artillery carriages apply equally in that of the ammunition-wagon, so far as the traveling conditions are concerned. It need only be observed that the general form of a limber-carriage can be most effectively retained in the ammunition-wagon by substituting a perch for the trail of the gun-carriage, and furnishing it with an eye in front for an attachment to the limber-hook. The arrangement of the ammunition-boxes on the platform of the body must be such as to insure the center of gravity of the entire load falling between the wheels and limber-hook, the pressure on the latter being regulated with particular reference to stability and ease of draught.

ANGLE OF DEFENSE: The intersection of two fortified lines - a salient angle pointed to the front, while a re-entering angle pointed to the rear.

ANGLES OF FIRE: The placement of a battery, or battery assignment, dictated the angle of fire used to achieve objectives. Angles of fire included:

Direct - battery of guns placed parallel to the face of the enemy’s works, or their line of troops, so that the projectiles struck it perpendicular.

Enfilade - battery of guns placed at right angles to the enemy’s works, or their line of troops, so that the projectiles fell in a parallel line to the works, striking a number of targets from one end of the line to the other.

Oblique - battery placed to form an angle with the front of the object to be struck.

Plunging - battery placed to fire projectiles from a higher position above the enemy’s works.

Reverse - battery placed to fire projectiles to strike the interior slope of the parapet at an angle greater than 30 degrees.

Ricochet - batteries fired at a slight elevation so that the shot bounced destructively from target to target along the enemy’s works or lines of troops.

Slant - battery placed so the shot struck the interior slope of the parapet, forming with it a horizontal angle, not greater than 30 degrees.

Vertical - batteries placed to fire a projectile at such an angle that it described a lofty curve through the air before it fell, such as the fire from a mortar battery.

ANVIL CAP: A flat piece of metal contained in a percussion fuze. Its purpose was to serve as a hard surface for the nipple to strike, thereby causing the spark necessary to detonate the powder in the chamber of the projectile.

APRON: A piece of sheet lead used to cover the vent of a cannon to protect against the elements. This was later replaced by the vent cover.

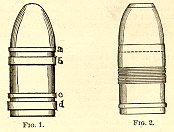

ARMOR-PIERCING PROJECTILES: Projectiles intended for practice at objects composed of wood, masonry, or earth are made of cast-iron; but since the introduction of iron for the defense of ships for fortifications, a material possessing greater hardness than ordinary cast-iron is required to overcome the resistance opposed by thick wrought-iron plates. Both elongated and spherical projectiles for use against armor should be of the hardest and toughest material possible. The power of a projectile to stand up to its work and deliver its full blow on the target depends on the shape as much as on the quality of the metal of which it is composed.

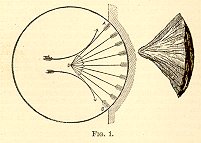

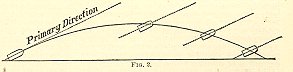

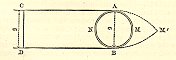

The resistance of the

plate, neglecting friction, acts as a normal to each point of the surface of contact of a

spherical projectile; thus, in Fig. 1 it will be seen that the portion of such a

projectile included between A and B, which we may term the zone of compression, is subject

to a crushing pressure towards the center, O, but it may be said to be under no tensile

strain. While the posterior portion of the projectile is suddenly checked by it in the

form of a wedge, when a portion of the work stored up inn it (the amount depending on the

tensile strength of the material of the projectile) is impressed on the target through the

front portion, AOB, while the remainder is carried off unprofitably in the fragments into

which the posterior portion breaks. On examining the projectile after impact, a part very

nearly corresponding to AOB in form will be found intact (Fig. 1) with the fractured

surface scored and polished, while the remainder will be disperses in small fragments. We

know that any casting fractures most easily in the direction of a normal to its surface,

the crystals settling themselves so as to form lines on this direction. Theoretically, the

portion represented by Fig. 1 ought to be smaller as the penetration is less – except

in the case of the entire blow being too small to overcome the tensile strength of the

metal in the manner described: when the projectile would only split irregularly, or, in an

extreme case, remain entire. In all instances obviously a great amount of the work, stored

up in the projectile is wasted; not that actually employed in breaking it, for such work

is clearly the result of the reaction from the target, but whatever power remains stored

up in the fragments after they sever themselves from the mass of the projectile. Since it

is impossible to predict what part of a spherical projectile fired from a smooth-bore gun

will come in contact with the target on impact, it is necessary that the material should

be such as will offer the greatest union of hardness, crushing strength, and tenacity;

therefore steel has been resorted to in some instances, and may be regarded as the

culminating point of development of the smooth-bore projectiles.

The resistance of the

plate, neglecting friction, acts as a normal to each point of the surface of contact of a

spherical projectile; thus, in Fig. 1 it will be seen that the portion of such a

projectile included between A and B, which we may term the zone of compression, is subject

to a crushing pressure towards the center, O, but it may be said to be under no tensile

strain. While the posterior portion of the projectile is suddenly checked by it in the

form of a wedge, when a portion of the work stored up inn it (the amount depending on the

tensile strength of the material of the projectile) is impressed on the target through the

front portion, AOB, while the remainder is carried off unprofitably in the fragments into

which the posterior portion breaks. On examining the projectile after impact, a part very

nearly corresponding to AOB in form will be found intact (Fig. 1) with the fractured

surface scored and polished, while the remainder will be disperses in small fragments. We

know that any casting fractures most easily in the direction of a normal to its surface,

the crystals settling themselves so as to form lines on this direction. Theoretically, the

portion represented by Fig. 1 ought to be smaller as the penetration is less – except

in the case of the entire blow being too small to overcome the tensile strength of the

metal in the manner described: when the projectile would only split irregularly, or, in an

extreme case, remain entire. In all instances obviously a great amount of the work, stored

up in the projectile is wasted; not that actually employed in breaking it, for such work

is clearly the result of the reaction from the target, but whatever power remains stored

up in the fragments after they sever themselves from the mass of the projectile. Since it

is impossible to predict what part of a spherical projectile fired from a smooth-bore gun

will come in contact with the target on impact, it is necessary that the material should

be such as will offer the greatest union of hardness, crushing strength, and tenacity;

therefore steel has been resorted to in some instances, and may be regarded as the

culminating point of development of the smooth-bore projectiles.

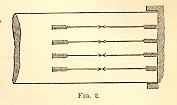

The flat-ended form of

elongated projectiles possesses a peculiar advantage as regards the projectile, and

another as concerns the plate. As to the projectiles, it may be seen (Fig. 2) that in

direct impact the whole of resistance of the target acts in lines parallel to the

projectile’s axis, which direction is the most favorable to the projectile retaining

its mass and delivering its full blow on the target; and, again, if the target is to be

punched by actual shearing, the flat head is the form best adapted to effect it. The flat

head would probably be best in the case of direct firing against plates composed of hard

iron, for it is easy to conceive of a hard material offering very great resistance to the

forcing open of a pointed head, which might be punched by the clean shearing of a

flat-headed projectile. The power given by rotation of keeping the same portion of a

projectile presented to the front is of peculiar value in punching armor-plates; it

enables the head of a projectile to be made of any desired form, while the power of

reducing the caliber of a projectile in proportion to its weight, which is perhaps the

principal advantage obtained by rifling, is also most important here, the depth of

penetration being in inverse proportion to the circumference. In shells, however, this

stability of the axis of rotation tells more fully, for it enables every part of the

projectile to be made of such proportions as will give the maximum power at the moment of

impact. The walls of an elongated shell being chiefly subjected to a longitudinal strain,

an interior hollow may be made without entailing the great weakness existing in spherical

shells as compared with solid shot. Hence it follows that while smooth-bore shells have

seldom or never been fired at armor, rifled shells have proved very successful.

The flat-ended form of

elongated projectiles possesses a peculiar advantage as regards the projectile, and

another as concerns the plate. As to the projectiles, it may be seen (Fig. 2) that in

direct impact the whole of resistance of the target acts in lines parallel to the

projectile’s axis, which direction is the most favorable to the projectile retaining

its mass and delivering its full blow on the target; and, again, if the target is to be

punched by actual shearing, the flat head is the form best adapted to effect it. The flat

head would probably be best in the case of direct firing against plates composed of hard

iron, for it is easy to conceive of a hard material offering very great resistance to the

forcing open of a pointed head, which might be punched by the clean shearing of a

flat-headed projectile. The power given by rotation of keeping the same portion of a

projectile presented to the front is of peculiar value in punching armor-plates; it

enables the head of a projectile to be made of any desired form, while the power of

reducing the caliber of a projectile in proportion to its weight, which is perhaps the

principal advantage obtained by rifling, is also most important here, the depth of

penetration being in inverse proportion to the circumference. In shells, however, this

stability of the axis of rotation tells more fully, for it enables every part of the

projectile to be made of such proportions as will give the maximum power at the moment of

impact. The walls of an elongated shell being chiefly subjected to a longitudinal strain,

an interior hollow may be made without entailing the great weakness existing in spherical

shells as compared with solid shot. Hence it follows that while smooth-bore shells have

seldom or never been fired at armor, rifled shells have proved very successful.

There are two causes which contribute to give shells peculiar power against iron plates. The first is that it is not necessary to weaken the head of a shell by making a fuze-hole in it; because no fuze is required, the heat generated on the impact of a projectile against the armor being sufficient to fire the bursting-charge. To such an extent is light as well as heat generated, that on firing oat a target after dark a pale flash is seen to follow the impact. The second cause that operates to favor the action of shells is the fact that when the shell has penetrated to a depth of even a few inches before rupture occurs, the sides are supported by the armor around them, and the explosion, being confined at the sides, acts to the front with greatly increased force.

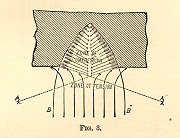

In a conical head the normal pressures throughout form a zone of compression acting as a wedge towards the body of the projectile, whose angle is the supplement of that of the cone of the head. This is better than that formed in the spherical head, because the angle is less acute, and because the apex of the wedge, instead of being a fixed point throughout (the center of the sphere), moves along the axis of the projectile as it enters deeper and deeper into the target. In the ogival head (Fig. 3) it will easily be seen how much superior is the action. In this the wedge is at the commencement slightly acute, but then the resistance acts on a small surface and is comparatively small, and the angle increases, till, at the junction of head and body, it becomes 180 degrees, or a straight line, so that we then have the body of the projectile in much the same condition as the flat headed bolt driving before it an ogival wedge, which opens the armor by wedging rather than by clipping or punching.

It is possible, no

doubt, to conceive of a material that might be sheared by the flat projectile more easily

than opened by the ogival; but it would be to contradict the results of experience to say

that plate-iron was such a substance; and as the softer and more plastic natures of

plate-iron have been found to hold their bolts the best, and stand the longest, and so

have been universally adopted, the ogival has become obviously the correct form of the

head.

It is possible, no

doubt, to conceive of a material that might be sheared by the flat projectile more easily

than opened by the ogival; but it would be to contradict the results of experience to say

that plate-iron was such a substance; and as the softer and more plastic natures of

plate-iron have been found to hold their bolts the best, and stand the longest, and so

have been universally adopted, the ogival has become obviously the correct form of the

head.

The effect of hardening projectiles is probably much greater than is

generally supposed; that is, the amount of work gained is much greater than the increase

of strength of the projectile. It is well known that a very small force may under certain

circumstances determine the performance or non-performance of a very large amount of work.

In like manner a very slight addition to the rigidity of a projectile, by hardening or

otherwise, may determine  whether a very

large amount of work shall be wasted upon the projectile or expended upon the plate.

Another means of increasing the work done upon the armor plate in comparison with that

done upon the projectile is by increasing the velocity of the latter. That is, a

projectile moving at a low velocity may be smashed up or flattened against the plate,

while the same projectile fired at a higher velocity may go through the same plate almost

uninjured. On this principle a lead shot may be fired through an iron plate, or a tallow

candle through a pine board.

whether a very

large amount of work shall be wasted upon the projectile or expended upon the plate.

Another means of increasing the work done upon the armor plate in comparison with that

done upon the projectile is by increasing the velocity of the latter. That is, a

projectile moving at a low velocity may be smashed up or flattened against the plate,

while the same projectile fired at a higher velocity may go through the same plate almost

uninjured. On this principle a lead shot may be fired through an iron plate, or a tallow

candle through a pine board.

Late trials have shown a superiority of steel projectiles over those made of chilled cast-iron; and although the former are somewhat more expensive than the latter, on the principle that the best is at the same time the cheapest, it would be misplaced economy to leave any means unavailed of to increase the penetrating power of projectiles. The quality of chilled projectiles, from the nature of their manufacture, is necessarily unreliable; whereas this is not the case with hammered cast-steel, or at least not to the same extent by far, even when large masses are produced; and the difficulty of manufacture increases with the caliber. The most essential difference in the behavior of steel and chilled projectiles on striking the target consists in the reaction on the projectile showing itself in the latter by breaking up, while the former are only set up. As the breaking up of the chilled shells may take place before the bursting-charge comes into operation, whereby the rending effect is considerably prejudiced, this material appears far less adapted for shells than steel. The superiority of steel in this respect is still further increased by the fact that the steel shell can have thinner walls, consequently a larger chamber, and can thus hold a larger bursting-charge than the chilled metal. – See Armor-plates and Projectiles.

ARMORER: One who was charged with the manufacture, repair, or preservation of weapons.

ARMORY: A manufactory or storage facility for arms and ordnance.

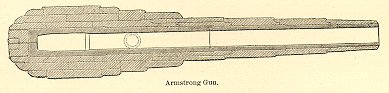

ARMSTRONG GUNS: The built-up gun construction of Great Britain, the germ of which is to be found in the coiled welded system of Sir William Armstrong, introduced to the artillery world in 1852 in the form of a breech-loading cannon, but passing from that date through numerous and important changes, especially the thickening of the coils and the introduction of tempered steel lining tubes, is the one which is still adhered to, in its general principles, by the ordnance constructors, both public and private, of the English nation. The failure of the Armstrong breech-loading guns, and the subsequent introduction of muzzle-loading cannon in lieu thereof, in 1869, did not change, however, one of the essential features of the present construction – the employment of coiled welded wrought-iron sections – but led to the modified form of their production known as the Fraser system, and the introduction of comparatively thin oil-tempered steel tubes for the interior lining. The most prominent guns produced under this new system, which first attracted universal attention on account of their great comparative power, were the 25-, 35-, and 38-ton guns; but these, as is well known, were quickly superseded by the 16-inch 80-ton gun, and it, in its turn, by the largest of, as yet constructed ordnance – the 100-ton guns of the Armstrong model, shown in section in the drawing.

The theoretical consideration that the ratio of the capacities for work of two tubes is only approximatively directly as their thicknesses, or, generally speaking, that a thin tube has more relative strength than a thick one to withstand interior bursting strains, is the essence of the theory of the built-up guns of the English model, and it is practically carried out in their present constructions; the inference to be drawn being that a homogeneous structure, having no subdivisions in its walls, does not bring into play the full strength of the entire thickness while under stress; and that guns constructed homogeneously, however thick, cannot long sustain pressures exceeding the tensile strength of the metal employed. Sanctioning the soundness of the theory that only by built-up constructions the most powerful and yet reliable guns can be produced, the next point for consideration is the arrangement of the different metals entering into the fabrication, so that the stronger metal (steel) shall form the walls surrounding the bore, and that the superimposed layers of wrought-iron shall be so placed on that each part, from the bore to the exterior, shall be, as far as possible, under strain in accordance with its capacity for work, considered in reference to tangential strains. The English authorities state: "This object we may obtain by employing a single metal for the several portions, and so disposing the various layers over each other that the inner layers or tubes are compressed by those outside them, while the exterior tubes are at the same time put into a state of tension, the inner layers being thus strengthened at the expense of the outer portions of the metal. In this case we obtain the whole strength of all the layers except a part of that of the outer and unsupported ring. It must not, however, be for one moment supposed that this theoretical perfection is ever reached; the nearest approach to it is far away from perfect, and theoretical advantages have to give way largely to practical considerations of manufacture. Again, we may arrive at a similar result by employing metals varying in elasticity or in tenacity for the several parts, those possessing the largest amount of strength constituting, of course, the inner portions, so that where the greatest stress is felt it will be borne by the stronger material. These two methods are sometimes called respectively those of initial tension and of varying elasticities. They may be, and frequently are, both employed in the manufacture of a gun, as in the case of the so-called Woolwich guns."

The longitudinal strain is provided for by the thick solid-bottomed steel tube, and the breech-plug screwed into the wrought-iron coiled tube, superimposing the inner tube, brings into play (in the latest model) the strength resulting from locking the tube and other parts together. The construction, briefly, we know is a steel tube, over which is shrunk coiled wrought-iron tubes; the majority of the larger calibers, except the 100-ton gun, having only two layers of wrought-iron tubes; the latter more perfectly brings into use the principles of initial tension, by having the wrought-iron casing subdivided into three instead of two parts. On theoretical considerations, the large number of coils employed in the original Armstrong construction enabled the designers more perfectly to carry out the idea of initial tensions by shrinkage; yet its expensiveness led to its abandonment, and the substitution of large and, in consequence, fewer coils; thus more imperfectly applying the principles which it was sought to follow as the true ones in making guns. Although economy, the object of the change, was attained, yet it is doubtful, from the large masses employed if the result is more than a very rough approximation to the asserted theories of construction. The broad differences in the physical properties of wrought-iron and steel, i.e., differences in elasticity and ductility and tensile strength, render problematical the perfect co-operation of the two metals, under repeated strains such as obtain in the use of guns; and it would seem that the more elastic and less extensible steel, in imparting its stress to the adjacent iron repeatedly, would enlarge the latter by degrees, so that eventually it would form but an imperfect support to the former, which would in that case more or less bear, in the system, the burden of the work in resisting tangential strains; and that its rupture under severer treatment would be finally the result. The manner in which this system in manufacture is practically carried out needs only, in view of the full description printed for public use, be but generally stated.

The tubes are generally of Firth’s production, and are furnished under contract to the Woolwich Arsenal. They are solid ingots which are first roughly bored and turned, and then tempered in rape-oil. The jackets or coils, shrunk over the steel tube, in the heaviest natures, range in number according to the length of the gun. Generally two layers of coils cover the breech part, all assembled in accordance with the principle of initial tension. The details of construction are fully given in English text-books, and need not be alluded to here. The 100-ton gun – the latest English muzzle-loading construction – generally speaking, differs from inferior calibers by the large number of shoulders provided on the steel tube, the latter being made in two parts, united together by a wrought-iron exterior band, and in the greater number of subdivisions of the jackets, or rather that the bands are relatively narrower than on other fabrications; besides, three layers obtain at breech, rendering it a more thoroughly built-up gun construction. Four of these guns – made by Sir William Armstrong & Co., Newcastle-on-Tyne – now form part of the armament of Great Britain and her Colonies, and now await their emplacements to be prepared for them at Malta and Gibraltar. We are informed that "guns have already been designed and could be readily made at Woolwich which would surpass the latter 100-ton gun’ in power to as great an extent as they themselves surpass the 38-ton service-gun."

The English Government establishment, however, has not produced any muzzle-loading constructions higher than the 80-ton gun, a gun, from the large facilities and perfected machinery of Woolwich, giving us the best exhibit of the Armstrong-Fraser system. That no recent attempts, however, to introduce higher natures of muzzle-loading guns have been made is fully justified by the important developments of Krupp’s experiments at Meppen in August, 1879, and by the disasters occurring on board the English iron-clad the "Thunderer" in the same year; the first calling attention to the presumed superiority of breech-loading guns – since accorded – in affording less exposure to men; reduced size of embrasures, securing greater rapidity of fire; increased length of bore, and hence greater power; and also affording greater facilities for bore examinations, and permitting an ease in loading not afforded in long-bored muzzle-loading guns; and the latter exhibiting the dangers arising from the possibilities of double charging, and the cumbersomeness and complica6tions of loading devices necessary for the use of muzzle-loading guns, more especially in the naval service, where economy of space is a matter of vital importance. Although the developments at Meppen and the Thunderer misfortune only occurred a few years ago, yet such was the moral effect that immediate steps were instituted to develop breech-loading guns of 12-inch caliber and lower natures.

The principal dimensions of the Woolwich and Elswick guns are as follows:

Woolwich. |

Elswick. |

|

| Total length of gun without carrier in. | 333 |

331 |

| Caliber…………………………….." | 12 |

12 |

| Bore: | ||

| In calibers……………………….." | 26 |

26 |

| In inches…………………………." | 312 |

312.2 |

| Total capacity…………………cubic" | 39,057 |

38,784 |

| Chamber: | ||

| Diameter…………………………." | 15.5 |

14.3 |

| Length……………………………." | 58.35 |

87.43 |

| Capacity………………………….." | 10,120 |

13,178 |

| Diameter in rear opening…………" | ……………………….. |

12.4 |

| Rifling: | ||

| Twist in calibers……………………… | ||

| Length…………………………….in. | ………………………. |

220.36 |

| Number of grooves……………….." | 48 |

50 |

These constructions (of the same caliber, 12 inch) differ very little from each other in their main features, such as modes of construction, principal dimensions, breech fermeture, and length of bore, the only important variations being in the lengths and diameters of chambers and their capacities; the Elswick gun having a less diameter and a greater length for this part of the bore, and also a greater capacity than the Woolwich pattern; this latter feature increasing the air-space in the chamber of the former over the latter when equal charges are used. It also, for the same diameter of the exterior, gives a stronger gun (both using the same metals) in its walls. A tabulated statement of these points of difference may be here inserted:

Powder-chamber. |

Powder-chamber. |

| Elswick: | R. G. F.: |

| Length……………in. 86.25 | Length……………in. 58.35 |

| Diameter………… in. 14.3 | Diameter…….……." 15.5 |

| Capacity…....cubic in. 13,178 | Capacity…… cubic " 10,120 |

The Woolwich authorities have established 17.1 tons per square inch as the service-limit for pressure, yet Armstrong for his constructions reaches 25 tons per square inch, and in his 10.15-inch wire gun a pressure of 34 tons per square inch has obtained. Cast-iron alone, or cast-iron in combination with wrought, or with wrought-iron and steel, or with steel alone, in guns for, say, one caliber and a half thickness of walls, cannot endure the chambering and in consequence the increased charges, which constructions made of steel alone, or steel in combination with wrought-iron, can sustain; and hence any plain using the inferior metal looking to a rivalry with the superior modern constructions which ignore the use of cast-iron would be a risk too hazardous to assume, and when the pressures reach, in guns using cast-iron, a limit of, say, not exceeding 35,000 to 37,000 pounds for a gun one and one half calibers thick, the service-limit should be regarded as reached, and the charges and chambering should be so regulated as to keep within these limits, which should be established as the limits of safety.

In steel guns a little less than one caliber is regarded as sufficient thickness of walls; and a caliber and one quarter, about, is used over the chambers of the 43-ton guns composed of steel and wrought-iron. In steel-tubed guns, surrounded by a wire and a part steel and part wrought-iron jacket, the thickness of walls given over the chamber is but eighty-five one-hundredths of a caliber. These figures illustrate the vast difference in the eyes of European gun constructors between the use of pure steel and the combination of steel and wrought-iron, and more especially in any construction in which cast-iron plays a prominent part. It would seem, therefore, independent of the recognized fact of the inferiority of cast-iron in strength, that the important element of weight would become largely a factor for consideration in judging of constructions using this metal, either alone or in combination with others. In fact as much power can be secured from a 43-ton (12-inch) gun (steel and iron) as from a 12-inch 55- to 60-ton gun (built-up) of cast-iron and steel.

In a 44-ton (13-inch)

wire gun we have the remarkable exhibit of a yield of 27,460 foot-tons muzzle-energy, or

say, 637 foot-tons per ton of metal. The cat-iron and steel constructions (60 tons)

alluded to above only give 359 foot-tons per ton of metal. The 10.15-inch wire gun

recently constructed has been tested, and the distinction between it and the

last-mentioned gun is more pronounced in favor of wire than the 13-inch; the resulting

muzzle-energy giving 760 foot-tons per ton of metal. The pressures are relatively higher

in attaining these results, yet the strength of the combination is believed to warrant a

large increase over the ordinary standard pressure adopted for the guns of the English

service. Admitting that about 37,600 foot-tons muzzle-energy can be attained with a

13-inch of a weight of, say 44 tons (wire), we find that it takes 50 per centum more

weight (60 tons) in a gun (12-inch) using cast-iron to attain a much less muzzle-energy

corresponding to the difference in calibers. The force of this testimony regarding weight

is evidently, as far as it goes, against the use of cast-iron; and when we consider the

question of its employment, pure and simple, this objection of increased weight necessary

in the structure becomes a subject of the first importance, and one alone which at the

threshold of the consideration of problem of gun construction should lead us to doubt if

it should be employed at all if we desire to attain a high standard in power and endurance

in our future heavy ordnance armaments.

In a 44-ton (13-inch)

wire gun we have the remarkable exhibit of a yield of 27,460 foot-tons muzzle-energy, or

say, 637 foot-tons per ton of metal. The cat-iron and steel constructions (60 tons)

alluded to above only give 359 foot-tons per ton of metal. The 10.15-inch wire gun

recently constructed has been tested, and the distinction between it and the

last-mentioned gun is more pronounced in favor of wire than the 13-inch; the resulting

muzzle-energy giving 760 foot-tons per ton of metal. The pressures are relatively higher

in attaining these results, yet the strength of the combination is believed to warrant a

large increase over the ordinary standard pressure adopted for the guns of the English

service. Admitting that about 37,600 foot-tons muzzle-energy can be attained with a

13-inch of a weight of, say 44 tons (wire), we find that it takes 50 per centum more

weight (60 tons) in a gun (12-inch) using cast-iron to attain a much less muzzle-energy

corresponding to the difference in calibers. The force of this testimony regarding weight

is evidently, as far as it goes, against the use of cast-iron; and when we consider the

question of its employment, pure and simple, this objection of increased weight necessary

in the structure becomes a subject of the first importance, and one alone which at the

threshold of the consideration of problem of gun construction should lead us to doubt if

it should be employed at all if we desire to attain a high standard in power and endurance

in our future heavy ordnance armaments.

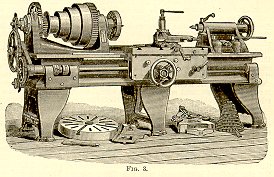

Independent of strength and increased weight, cast-iron guns of heavy natures require a cumbersome and expensive plant, consisting of deep pits, large furnaces, powerful cranes, and heavy and powerful lathes, etc., whereas in the built-up steel, and steel and wrought-iron systems, also wire guns, the numerous parts which go to make up the whole can, from their comparative lightness, be handled in the different operations of construction with far greater ease and less expense than obtain in the production of homogeneous masses consisting of but one piece, as found in systems where cast-iron enters either solely or largely into the fabrications. On the score of economy, it may be doubtful if any material advantage results in the use of cast-iron. English models cost about 14 cents per pound. To gain equal powers we would require, according to the ideas of constructors in cast-iron, at least a 60-ton gun to perform the same work as a 43-ton gun of steel and wrought-iron. If we estimate cast-iron at 12 cents per pound, we have a cost of $16,128 for a pure cast-iron gun of 60 tons; and admitting 14 cents per pound for wrought-iron and steel, we have a cost for a 43-ton gun of $13,484.80. If a net profit of 25 per centum for manufacturers is added to this latter figure, which is government cost, we have even then a less expensive construction than pure cast-iron in that country. See Built-up Guns and Ordnance.

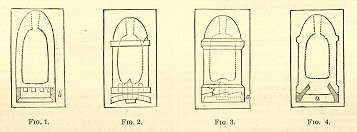

ARMSTRONG PROJECTILE: But one kind of projectile is used in the Armstrong breech-loading guns for the field-service, and this is so constructed as to act as a shot, shell, or case-shot, at pleasure. It consists, as shown in Fig. 1, of a very thin cast-iron shell, snugly inclosing forty-two segment-shaped pieces of cast-iron (B B), built up so as to form a cylindrical cavity in the center (D), which contains the bursting-charge and the concussion-fuze. The exterior of the shell is thinly coated with lead (C C), which is applied by placing the shell in a mold and pouring it in a melted state. The lead is also allowed to percolate among the segments, so as to fill up the interstices, the central cavity being kept open by the insertion of a steel core. In this state the projectile is so compact that it may be fired without injury; while its resistance to a bursting-charge is so small that less than one ounce of powder is required to burst it. When the projectile is to be fired as a shot, it requires no preparation; but the expediency of using it otherwise than as a shell is doubted.

To make it available as a shell, the bursting-tube, the concussion- and time-fuzes, are all to be inserted; the bursting-tube entering first, and the time-fuze being screwed in at the apex. If the time-fuze be correctly adjusted, the shell will burst when it reaches within a few yards of the object; or, failing in this it will burst by the concussion-fuze when it strikes the object or grazes the ground near it. If it be required to act as a canister-shot upon an enemy close to the gun, the regulation of the time-fuze must be turned to the zero of the scale, and then the shell will burst on leaving the gun. The explosion of one of these shells in a closed chamber, where the pieces could be collected, resulted in the following number of fragments; 106 pieces of cast-iron, 90 pieces of lead, and 12 pieces of fuze, etc. – making in all 217 pieces.

The Armstrong projectiles for the muzzle-loading guns have rows of

brass or copper studs projecting from their sides to fit into the grooves of the gun,

which are constructed on the shunt principle. Fig. 2 represents a 10-inch Armstrong Shell

for penetrating armor-plates;  It is made of

wrought-iron or low steel, with very thick sides. There is no fuze, the explosion

resulting from the heat generated by the impact, and the crushing in of the thin cap which

closes the mouth of the powder-chamber. The sides and bottom of the shell being thick

enough to resist crushing by the impact, and also to resist the explosive force of the

bursting-charge, its effect will, after penetration, be expended on the backing of the

armor, or the decks which the armor is intended to screen. Such projectiles are called

"blind shells." See Projectiles.

It is made of

wrought-iron or low steel, with very thick sides. There is no fuze, the explosion

resulting from the heat generated by the impact, and the crushing in of the thin cap which

closes the mouth of the powder-chamber. The sides and bottom of the shell being thick

enough to resist crushing by the impact, and also to resist the explosive force of the

bursting-charge, its effect will, after penetration, be expended on the backing of the

armor, or the decks which the armor is intended to screen. Such projectiles are called

"blind shells." See Projectiles.

ARSENAL: A storage facility for ordnance and ordnance stores. Some arsenals were also used for the construction and repair of ordnance equipment.

ARTIFICER: Military workmen. Each artillery company was allowed two artificers.

ARTILLERIST: A soldier serving with the artillery.

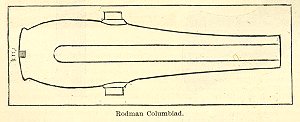

ARTILLERY: 1) Generic term used to describe the heavy weapons of every description with the implements and materials necessary for their use. The weapons are broken down into four categories: Guns, Howitzers, Columbiads, and Mortars. These pieces are further categorized by their specific use: Seacoast, Siege and Garrison, and Field Artillery. Finally, artillery weapons may be denoted by type of bore (smooth or rifled). 2) Specific branch of the Confederate and Union armies and navies charged with the deployment, service, and maintenance of artillery. 3) Sub-units of the artillery branch, usually designated by state name, regiment number and/or name, battery letter, corps number, and specific army membership. Many of the sub units were also known by the name of their commanding officer or other non-standard references.

ARTILLERY CREW: Military personnel responsible for the maintenance, transportation, and operation of the various artillery pieces and the equipment and horses needed to properly support the battery. Each crew member working the cannon was assigned a number which dictated what his specific responsibility was during each phase of the operation of the guns. Support personnel included horse drivers, horse holders, and specialized functions such as blacksmiths. A Union army battery, at full strength, exceeded 100 officers and men.

ARTILLERY HORSES: See Horse Team.

ARTILLERY PARK: 1) A space occupied by animals, wagons, and artillery contiguous to a military camp. 2) A collection of one or more batteries.

ARTILLERY RESERVE: Designated batteries which were to remain limbered and hitched, ready to move quickly into position during battle. Their purpose was to replace disabled batteries or to move rapidly where the enemy was massing for an attack. The Army of the Potomac had a designated artillery reserve which practiced such maneuvers.

ARTILLERY SABER: A large, thick, curved blade having no basket guard often referred to as a saber.

ARTILLERY TRAIN: A military organization consisting of varying numbers of artillery weapons proportioned according to caliber and type. Siege weapons (guns, howitzers, mortars) were usually organized in trains of 100 pieces along with the required carriages, horses, ammunition, and gunpowder. Field trains were considerably smaller, usually consisting of three field weapons (guns and howitzers) per 1,000 infantry.

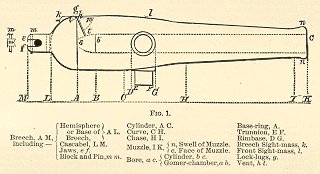

ASTRAGAL: Small convex molding used in the ornamental work of the cannon tube. It was usually connected with a fillet or flat molding.

AUGET: A groove on a traversing gun carriage which directed the recoil of a gun.

AXIS OF THE PIECE: The central line of the bore of an artillery tube.

BALLISTIC PENDULUM: An instrument which determined the force and velocity of a projectile during its flight.

BAR SHOT: Two hemispheres, or round shots, connected together by a short iron bar. When this shot was fired it began a rotation which, in theory, was supposed to cut the masts and rigging of naval vessels.

BARBETTE: Artillery elevated to fire above the crest of a parapet rather than through an embrasure. This was done by either raising the earth behind the parapet, or by placing the weapon on a high carriage. The advantage of barbette firing was a much wider range of fire unrestricted by the small embrasure.

BARBETTE CARRIAGE: An immovable wrought iron or heavy wooden carriage used for the mounting of garrison and seacoast artillery. Two varieties of the barbette carriage were the front-pintle (for the 8- and 10-inch Columbiad, and the 24-, 32-, and 42-pounder gun) and the center-pintle carriages (for the 8- and 10-inch Columbiad).

BARREL: See Tube.

BASE LINE: A line traced around the gun in the rear of the vent.

BASE RING: A projecting band of metal which adjoined the base of the breech, and was connected to the body of the gun by a concave molding.

BATTERIES: A battery consists of two or more pieces of artillery in the field. The term battery also implies the emplacement of ordnance destined to act offensively or defensively. It also refers to the company charged with a certain number of pieces of ordnance. The ordnance constitutes the battery. Men serve the battery. Horses drag it, and epaulments may shelter it. A battery may be with or without embrasures. In the latter case it is en barbette, and the height of the genouillere varies according to the description of the gun-carriage used. The ordnance constituting the battery requires substantial bearings either of solid ground for field-pieces, or of timber, plank, or masonry platforms, for heavy artillery. Batteries are sometimes designated as follows: Barbette battery, one without embrasures, in which the guns are raised to fire over the parapet; Ambulant battery, heavy guns mounted on traveling carriages, and moved as occasion may require, either to positions on a coast, or in besieged places; Covered battery, intended for a vertical fire, and concealed from the enemy; Breaking battery; Joint batteries, uniting their fire against any object; Counter battery, one battery opposed against another; Coast battery; Direct battery; Cross batteries, forming a cross fire on an object; Oblique battery, forming an angle of 20 degrees or more with the object against which it is directed, contradistinguished from direct battery; Raised battery, one whose terre-plein is elevated considerably above the ground; Sunken-battery, where the sole of the embrasures is on a level with the ground; and the platforms are consequently sunk below it; Enflading battery, when the shot or shell sweeps the whole length of a line of troops or part of a work; Horizontal battery, when the terre-plein is that of the natural level of the ground, consequently the parapet alone is raised and the ditch sunk; Open battery, without epaulment or other covering, wholly exposed; Indented battery, or battery a cremaillere, battery constructed with salient and re-entering angles for obtaining an oblique as well as a direct fire, and to afford shelter from the enfilade fire of the enemy; Reverse battery, that which fires upon the rear of a work or line of troops; Ricochet battery, whose projectiles, being fired at low angles, graze and bound without being buried; Masked battery, artificially concealed until required to open upon the enemy.

Field-batteries, in sieges, are usually of two kinds, viz., Elevated batteries and Sunken batteries, and they are placed either in front of the parallel, in the parallel itself, or in rear of it. In an elevated battery, the platforms for the guns or mortars to stand upon are laid on the natural level of the ground, and the whole of the covering mass, or parapet, is raised above that level, the earth for forming it being obtained from a ditch in front. In a sunken battery, the whole interior of the battery is excavated about three feet deep, and the platforms laid on the bottom, the earth is thrown to the front, and the parapet is formed out of it. Great care must be taken that no rise in the ground before the battery obscures the view from the soles of the embrasures; for this purpose, the officer laying out the battery should lie down and look along the ground, in order to be sure that his guns can range freely from their embrasures before he fixes his details for construction. When guns are fired with an elevation, when the soil is sandy or gravelly, when the weather is dry, or the ground elevated, this construction is approved. The depth of the excavation for the interior must depend on the height of the carriages upon which the guns are mounted: it should be deeper in rear than in front, that it may be drained. The interior slopes of these batteries, and the cheeks of the embrasures must be supported by field-revetments of gabions, fascines, sand-bags, casks, or sods. In batteries exposed to a heavy fire, especially of shells, it is necessary to provide as much cover as possible for the men serving in them; for this purpose, traverses are usually placed between every two guns; and as these masses serve to protect the men from the splinters of the bursting shells, they are generally called splinter-proof traverses. There is nearly twice as much work in the elevated as in the sunken battery.

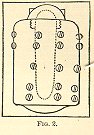

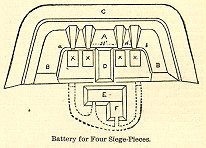

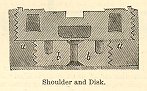

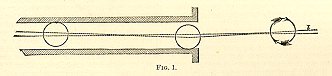

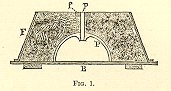

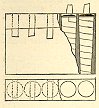

A battery for four siege-pieces is represented in the drawing. In this construction, the parapet (A) is made of earth taken from the front, thus forming a ditch (C).

To protect the pieces

(XXXX) from flank fire, the parapet is continued around on one or both ends, forming

epaulments (BB). The guns are in pairs, separated by a traverse (D). The interval between

the axes of the embrasures of each pair is 16 feet for guns on traveling carriages, and

from 18 to 22 feet for sea-coast guns. Between the two middle pieces this distance is

increased by the thickness of the traverse, generally about 15 feet. The entire length of

the interior crest of the parapet, from a to b, will therefore be 79 feet. This and other

given dimensions are not absolute, but indicate the method of obtaining the data necessary

for laying out any battery. The length of the flank epaulments will depend upon the

direction of the enemy’s fire; in all cases it must be sufficiently great to give

full protection to the whole interior from an enfilading fire; generally it would be about

24 feet. The thickness of the parapet and epaulments will depend upon the power of the

artillery they are expected to resist.

To protect the pieces

(XXXX) from flank fire, the parapet is continued around on one or both ends, forming

epaulments (BB). The guns are in pairs, separated by a traverse (D). The interval between

the axes of the embrasures of each pair is 16 feet for guns on traveling carriages, and

from 18 to 22 feet for sea-coast guns. Between the two middle pieces this distance is

increased by the thickness of the traverse, generally about 15 feet. The entire length of

the interior crest of the parapet, from a to b, will therefore be 79 feet. This and other

given dimensions are not absolute, but indicate the method of obtaining the data necessary

for laying out any battery. The length of the flank epaulments will depend upon the

direction of the enemy’s fire; in all cases it must be sufficiently great to give

full protection to the whole interior from an enfilading fire; generally it would be about

24 feet. The thickness of the parapet and epaulments will depend upon the power of the

artillery they are expected to resist.

Batteries for even the heaviest pieces may be constructed on marshy ground by laying a grillage of timber over the surface and building up the parapet on it with sand-bags. To prevent the parapet from settling over towards the front, the grillage should extend several feet beyond it in that direction. In order that the platform of the piece may not be moved from its true horizontal position by any settling of the parapet, the space to be occupied by it is enclosed with strong sheeting piles. In this enclosed space several layers of fascines are laid, crossing each other at right angles; on these earth or sand is rammed, and the platform laid in the usual manner. If sand is used on top of the fascines, two or three thicknesses of paulins should be spread over them to hold the sand. Magazines in such localities must, of necessity, be entirely above ground, and supported on grillage in the same manner. See Embrasure.

BATTERING CHARGES: In the service of artillery there are two classes of cartridges, battering and full. The first is used with Palliser projectiles, and only under certain circumstances with common shell; the second is the ordinary charge used with common, double, shrapnel shell, and case-shot. The powder used would be pebble for all battering charges, and for full charges of 40 pounds and upwards.

The reason why pebble-powder is now used with all large guns instead of ordinary powder is explained as follows: That the pressure on the gun is much less, and the velocity greater, with the former than the latter. This increased velocity is due to the lower pressure of the powder, which is kept up longer in the bore than with quicker-burning powder, the velocity depending upon the pressure and the space over which it is exerted.

BATTERING PROJECTILES: Projectiles for battering purposes are made of cast-iron, chilled iron, and steel. Against parapets of earth common shell containing large bursting-charges are the most effective. Compound shot, having chilled cast-iron heads and cast-steel bodies, give good results, but they lack the power to carry their bursting-charge behind the armor which they can penetrate. The hardness and tenacity of steel shot and shell make them very effective against all kinds of armor. The great cost prevents their use when good results can be accomplished by chilled shot. Gunpowder is not a sufficiently powerful explosive for these strong shells, and, moreover, it explodes on impact. Satisfactory experiments have been made with bursting-charges of gun-cotton, which only explodes when the penetration is complete. Both forged and cast steel shells, well tempered, have perforated great thicknesses of wrought iron, in direct hitting, without being injured. Cast-steel projectiles, compressed by an hydraulic press while in a fluid state to drive out bubbles, give excellent results. In direct fire against steel-faced armor, cast-steel shells, owing to their great hardness, behave better than those of forged steel. The reverse is the case in oblique fire, where tenacity and toughness are the main considerations. All steel projectiles thus far tried break up against steel-faced armor in oblique fire. The longer the head of the projectile the greater the effect in direct fire, while for oblique fire the best effects are obtained with heads struck with a radius of two diameters. The flat-headed projectiles are much inferior to those with pointed heads in both direct and oblique fire. The respective advantages of light and heavy shells may be said to be as follows, assuming the powder-charge to be constant: The heavier shells, though starting with a lower initial velocity, keep up their velocity better than lighter ones, and so have a longer range of penetrative effect. The lighter shells have a higher velocity at short ranges, and a flatter trajectory; also, a greater number can be carried for a given weight. The projectile must no be so heavy as to strain the gun unduly, but this is easily avoided by the use of slow-burning powder and air-spacing. The cavity in shells should be as capacious as possible, so as to carry a large bursting-charge, but this will be controlled by the thickness which the head and walls must possess to give the necessary strength. See Armor-plates.

BATTERY: A term applied to one or more pieces of artillery, or to the place where they were positioned. In the Union army a battery was usually made up of six pieces of the same kind of cannon, while a battery in the Confederate army usually constituted four weapons. Batteries, under the command of a captain, were further broken down into sections. Each section consisted of two guns under the command of a lieutenant. One gun, along with a caisson and limber, was designated as a platoon and served under a sergeant and two corporals. A battery in the Union army could exceed 100 men and officers.

BATTERY ASSIGNMENT: Batteries were often assigned by how or where they were in position (served), or by a specified purpose in battle. The usual assignments were:

Ambulant - heavy weapons mounted on traveling carriages and moved, as circumstances required, to positions on a coast or to locations under siege.

Barbette - battery with no embrasures. Weapons were raised to fire over the parapet.

Breaching - sustained, directed fire against a specific target such as a fort wall. The purpose was to punch a hole through the target, thereby weakening or destroying it.

Coast - heavy weapons mounted permanently or semi-permanently for defense on the coast.

Counter - one battery opposed against another.

Covered - a battery intended for vertical fire and concealed from the enemy.

Cross - batteries which formed a cross fire on any object.

Defilade - batteries protected from a plunging fire directed from adjoining heights.

Direct - a battery ranged parallel to the face of the target so shot could strike perpendicularly.

Enfilading - shot or shell which swept the whole length of a line of troops or part of a work.

Horizontal - terreplein was that of the natural level of the ground, and the parapet alone was raised and the ditch sunk.

In Battery - siege battery with its guns run forward into embrasures, or a field battery with its guns unlimbered ready for action.

Indented - constructed with salient and re-entering angles for obtaining an oblique, as well as direct fire, and afforded shelter from the enfilade fire of the enemy.

Joint - batteries uniting fire against any object.

Masked - batteries artificially concealed until required to open upon the enemy.

Oblique - a battery which formed an angle of 200 or more with the object against which it was directed.

Open - a battery without epaulment or other covering, wholly exposed.

Plunging - shot fired from a position considerably higher than the target.

Raised - terreplein was elevated considerably above the ground.

Reverse - batteries which fired upon the rear of a work or line of troops.

Ricochet - batteries which fired projectiles at low angles. The projectiles grazed the ground or water and bounced without being buried.

Sunken - the base of the embrasure was on a level with the ground and the platforms were consequently sunk below it.

BATTERY-GUN: A gun having a capacity for firing a number of shots consecutively or simultaneously without stopping to reload. There are many varieties.

- A piece of ordnance having a number of load-chambers attached to a vertical axis, and consecutively presented at the rear of the cannon-bore. As each takes its place at the breach, it is advanced into the bore and locked before firing.

- A chambered breech-piece, revolving in a vertical plane, and presenting its chambers consecutively at the open rear of the barrel, which is common to all the chambers. The principle of construction is that of the revolving chambered pistol.

- A number of parallel barrels arranged in rank, and having connected vents for intercommunication of fire. The infernal-machine of Fieschi, which he fired on Louis Philippe, was a row of barrels clinched to a frame, and had a train of powder which was laid over all the vents in succession, like the row of barrels in a proving-house.

- Forms of many-barreled cannon revolving on a vertical axis, the pieces being muzzle-loaded.

The Requa battery consists of 25 rifles, each 24 inches long, mounted in a horizontal plane upon a field-carriage. It is breech-loading, the cartridges being forced into the chambers by a sliding-bar worked by two levers. By a lever beneath the frame the barrels may be diverged , so as to scatter the balls 120 yards in a distance of 1000 yards. The weight of the battery-gun used at Charleston, S. C., was 1382 pounds. Served by three men, it fired seven volleys, or 175 shots, per minute. Its effective range was 1300 yards.

BATTERY WAGON: A two-wheeled cart used to carry the tools and supplies necessary to keep the leather, cloth, and wood equipment of the battery in good condition. It was linked to the limber to form a four-wheeled vehicle.

BATTLEMENT: A wall or parapet with indentations or notches.

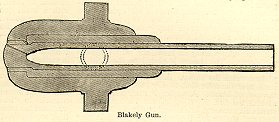

BLAKELY GUN: The most approved pattern of the Blakely gun combines in its construction the principles of "initial tension" and "varying elasticity," the object of which is to bring the strength of all the metal of the piece into simultaneous play, to resist explosion.

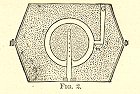

The drawing shows the

general features of the gun. The inner tube, or barrel, is made of low steel, having

considerable but not quite enough elasticity. The next tube is made of high steel with

less elasticity, and is shrunk on to the barrel with just sufficient tension to compensate

for the insufficient difference of elasticity between the two tubes. The outer cast-iron

jacket, to which the trunnions are attached, is the least elastic of all, and is put on

with only the shrinkage attained by warming it over a fire. The steel tubes are cast

hollow and hammered over steel mandrels, under steam-hammers: by this process they are

elongated about 130 per cent; at the same time the tenacity of the metal is increased. All

the steel parts are annealed.

The drawing shows the

general features of the gun. The inner tube, or barrel, is made of low steel, having

considerable but not quite enough elasticity. The next tube is made of high steel with

less elasticity, and is shrunk on to the barrel with just sufficient tension to compensate

for the insufficient difference of elasticity between the two tubes. The outer cast-iron

jacket, to which the trunnions are attached, is the least elastic of all, and is put on

with only the shrinkage attained by warming it over a fire. The steel tubes are cast

hollow and hammered over steel mandrels, under steam-hammers: by this process they are

elongated about 130 per cent; at the same time the tenacity of the metal is increased. All

the steel parts are annealed.

Captain Blakely uses other combinations of these metals, the simplest of which is a cast-iron gun with hoops of steel surrounding the reinforce. He objects to the use of wrought-iron on account of its tendency to stretch permanently. Blakely guns are rifled with one-sided grooves, and are fired with expanding projectiles. The following are the dimensions, etc., of Blakely all-steel guns:

Gun. |

Weight |

Diam. Of Bore. |

Length Of Bore. |

No. of Grooves. |

Twist. |

Weight of Projectile |

Weight of Powder |

Lbs. |

In. |

In. |

1 turn in Calibers. |

Lbs. |

Lbs. |

||

| 100-pdr…. | 8,000 | 6.4 | 96 | 8 | 48 | 100 | 10 |

| 120-pdr…. | 9,000 | 7 | 100 | 8 | 48 | 120 | 12 |

| 200-pdr…. | 17,000 | 8 | 44-156 | 12 | 48 | 200 | 20 |

| 250-pdr…. | 24,000 | 9 | Do. | 12 | 48 | 250 | 25 |

| 350-pdr…. | 30,000 | 10 | Do. | 15 | 48 | 350 | 35 |

| 350-pdr…. | 35,000 | 11 | Do. | 12 | 36 | 550 | 55 |

| 700-pdr…. | 40,000 | 12 | Do. | 12 | 36 | 700 | 70 |

See Ordnance.

BLAKELY PROJECTILE: This projectile has an expanding copper cup attached to its base by means of a single tap-bolt in the center, or other simple means. It is prevented from turning by radial grooves cast on the surface of the bottom of the projectile, into which the cup is pressed by the charge. The angle between the curved sides of the cup and the bottom of the projectile is filled with a lubricating material. On the forward part of the body are soft metal studs, more numerous than the grooves of the bore of the piece, that some of them may always form a bearing surface for the projectile against the lands. The driving sides of the grooves are deeper than the other. See Expanding Projectiles.

BLANK CARTRIDGE: A cartridge filled with powder, but having no projectile.

BLIND SHELL: A projectile with a hollow cavity which was plugged and not intended to have been fitted with a fuze. This projectile weighed less than a solid shot of the same caliber, which increased its velocity when it was fired. This shell which was similar to the cored-shot, also decreased the strain on the cannon.

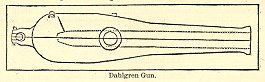

BOAT GUN: Brass weapon designated by the Navy to be mounted on smaller boats for use on waterways and coastal areas. The primary guns were 12- and 24-pounder smoothbores and the 12-pounder rifled Dahlgren howitzer.

BOLSTER: A block of wood on the carriage of a siege gun. The breech rested on this when the piece was moved from place to place.

BOLT: See Solid Shot.

BOMB: A missile which also receives the names of bomb-shell and shell. It is a hollow ball, usually of cast-iron, fired from a mortar or other large piece of ordnance, and filled with combustibles which work great havoc when the ball bursts by the firing. All such projectiles were formerly fired from mortars only, and there was thus a definite relation between the bomb and the mortar; but since the invention of shell-guns and other modern pieces of artillery, the name shell has been generally substituted for that of bomb. The 13-inch bomb, which is the largest size used in ordinary warfare, weighs about 195 pounds., with a thickness of metal varying from 1 ½ to 2 inches at different parts; it bursts with about 8 pounds. of powder. The vent through which it is filled with powder is, after the filling, closed with a plug called a fuze, which sets fire to the powder, and at the proper moment bursts the bomb into fragments. The 10-inch bomb, weighing about 90 pounds., is proportionally less in all dimensions than that just described; and so on for those of smaller diameters. It should be understood, however, that the above are conventional quantities prescribed and adopted more than half a century ago. Modern artillerists try experiments on bombs of various degrees of thickness with various charges and fuzes. See Shell.

BOMB CHEST: A chest of powder placed underground which caused destruction when exploded by a fuze.

BOMB-KETCH: Also known as Bomb-Vessel. A small naval vessel strongly constructed to serve as a floating platform that supported the weight of and firing of a mortar or to transport mortars.

BOMB-PROOF: A term applied to military structures of such immense thickness and strength that bombs cannot penetrate them. Military buildings generally within permanent fortifications, and which are formed so as to withstand the shock of heavy shot or shell falling on them. Magazines for holding gunpowder should be placed in the most sheltered position within a fortress, and strongly constructed to resist direct and vertical fire from heavy ordnance. In the forts recently built for coast-defense in England, 17 feet of masonry as been considered necessary against direct fire, and an arch 3 feet thick, with 3 feet of concrete over the roof, against vertical fire.

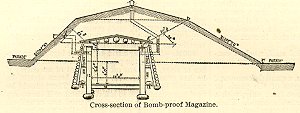

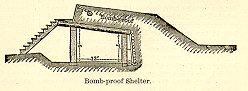

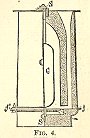

BOMB-PROOF MAGAZINE: For field-works of a semi-permanent character which are to be

indefinitely occupied, have an armament of heavy guns, and are expected to stand a siege,

- like the defenses around Washington, for example, - the magazines, bomb- and

splinter-proof shelters should be constructed of the heaviest timber, and be covered

securely with earth from the assailant’s curvated and direct fire. The ventilation of

the magazines and precautions for their drainage are of the utmost importance. The drawing

shows a cross-section of a magazine constructed in a work of this character. The sides of

the interior of the magazine are formed of twelve-inch logs placed vertically in

juxtaposition and resting upon a ground-sill. These are capped on top by a two-inch board,

a strip of a like kind being spiked on within the cap. The top is formed of fifteen-inch

logs, also in juxtaposition, each having a shoulder of three inches to fit it to the cap

and inside strip. Longitudinal logs are laid on these with varying diameters, so as to

give a proper pitch for the roof. Earth is solidly packed upon the top and between the

roof-logs, receiving the proper slope for the roofing-boards. These boards, carefully

jointed, are laid on in two thicknesses, each being covered with a coating of asphalt. The

flooring of the magazine is of joists and boards. The sides of the magazine are surrounded

with an air-chamber formed by inclined logs supported on a ground-sill and resting against

the top logs; these are placed at three or four feet apart, each one being braced at the

middle point to resist flexure from the pressure of earth. The chamber is covered in by

saplings laid in juxtaposition. There are ventilators between the magazine and the

air-chamber near the top, and also between the latter and the external air; the two not

being opposite, and the usual precautions to guard against accident from sparks being

taken. The earth-cover is ten feet on the exposed side, and six feet on the other sides

and on top. The entrance to the magazine is well secured by a bomb-proof covering. A slope

is given from the interior to the foot of the steps leading to the level of the floor for

the purposes of draining.

BOMB-PROOF QUARTERS: Casemated bomb-proof quarters are indispensable to the safety and comfort of the garrison during siege, or any prolonged attack for the annoyance of reduction of the work by a bombardment. In small works like most of our forts, which are chiefly designed for sea-coast defense, casemated quarters have been generally arranged in the rear of the batteries a portion of each casemate towards the parade being partitioned off and suitably disposed for the object in view. In some cases advantage is taken of a scarp-wall, on a land-front, which is well covered by a glacis or other face-cover, to form in its rear quarters of this character. In all cases care should be taken to place such quarters on those fronts which are best covered from a direct fire, and the parade-walls of which are not exposed to reverse-fire. Whenever the plan of the work admits of it, quarters of this kind should be arranged for defense, by being pierced with loop-holes and even with embrasures for cannon. Defensive casemated quarters form a prominent and distinctive feature in what is now known as the German School of Permanent Fortification.

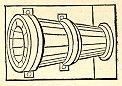

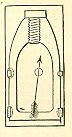

BOMB-PROOF SHELTERS: These structures are for the protection of the troops when not on

duty. They should be located on the parade, convenient to the pieces to be served, yet not

so near as to interfere with the defense. They are usually constructed in half-excavation

of logs built up like a log-house, or of a framework in the manner shown in the drawing,

the exterior side being of heavy logs placed vertically in juxtaposition, resting on a

ground-sill and capped at top. Parallel to this is another row, forming the other side,

which may also be placed side by side or at short intervals apart, and capped like the

outside row. The roof, consisting of heavy logs laid in juxtaposition and covered with

thick boards joined, rests on the capping, the whole covered over on the side of the enemy

with earth to a depth of at least 14 feet from the wood-work. To prevent this mass of

earth from pushing the structure over to the rear, one in every two or three of the

roof-logs is cut of sufficient length to extend about 8 feet beyond the front of the wall,

and dovetailed to a longitudinal log help in position by vertical posts, the anchor-log

being sufficiently covered with earth to protect it from injury by shot from the enemy.

These bomb-proofs are made to serve the purpose of traverses, and are frequently arranged

with a staging or gallery along the rear side for the accommodation of infantry, who

deliver their fire over the top, arranged for this as a parapet. In all interior

arrangements, system and regularity should be observed from the first; otherwise the work

will grow into a labyrinth of confusion greatly opposed to efficiency and comfort. See

Shelters and Splinter-proof Shelters.

BOMBARD: An ancient piece of ordnance, which was very short, thick, and wide in the

bore. It differed from the balista in being worked with gun-powder instead of by

mechanical force, and from the mortar in shooting forth stones instead of iron shells.

Some of the bombards used in the fifteenth century propelled stones weighing from 200 to