Dr. John Braham Read

Dr. John B. Read was a surgeon and projectile inventor from the town and county of Tuscaloosa, Alabama. Dr. Read's public experiments were conducted during a three year period before the close of 1859. Most of the experiments with projectiles and their sabots were at his own expense. Read's first patented invention was the "Improved Mode of Constructing Projectiles for Cannons" that he patented on October 28, 1856, United States patent #15,999. His patent states:

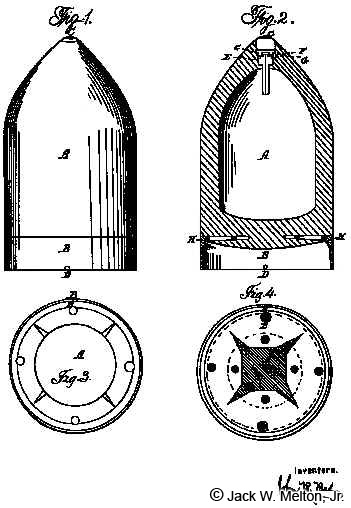

"The nature of my invention consists in the attachment to the butt of elongated cannon shot or shells of a cupped cylinder of wrought-iron fastened to the body of the shot or shell by having its perforated bottom embedded in the cast-iron or other metal of which the shot may be composed, while its sides project beyond and are so thinned down as to be capable of such expansion by the charge of the gun on firing as to fit its bore exactly, thus saving windage in all cases and imparting rotary motion to projectiles when rifle-grooves or their equivalents are employed, thus securing, by the striking of the projectile upon its apex, the important advantage of using percussion-shells." He discusses the installation of the wrought-iron sabot "...by whatever mode it may be formed, is to be placed in the bottom of the mold formed by the pattern for the shell, and the projectile completed by pouring the necessary amount of cast metal." This is the method that the Confederates manufactured the Read projectile. The sabot was cast first then placed into a projectile mold, and the molten iron poured around it, thus securely embedding it in the base. This method was adopted by the Confederate foundries as the most acceptable form of attaching a sabot to a rifled projectile.

Read's patent also covers almost every possible way to attach a sabot to the bottom of a rifled projectile as it states: "It is evident that the wrought-iron cylinder might be attached to the body of the shot in several different ways, as by leaving the large central aperture round and cutting in it a female screw to take hold of a projectile from the bottom of the shell; or the bottom of the cupped cylinder might be omitted entirely and the sides nearest the butt be cut with a female screw large enough to receive the butt of the shot; or the cupped cylinder may be made without apertures, but with rough and projecting points, as where the mouth of a filled sack is tied, and these might be embedded in the cast metal; or the cylinder may be fastened on by screws or rivets to the body of the shell without being united with it in founding; or the cylinder may embrace the sides of the shell more or less or envelop it at its apex, being fastened on with cast or wrought [iron] rivets or screws or by brazing; but none of these methods can compare with the economical, solid, and easy mode of union which I have indicated, and they are only mentioned to prevent future claims for improvements." Since Read covered about every conceivable way to attach a sabot to a projectile, it leaves the students of ordnance unsure as to what to call certain types of projectiles. For example, the Parrott and Broun projectiles with the high-brass and copper bands, "...the cylinder may embrace the sides of the shell more or less..." and Mr. Mullane [the Tennessee Sabot] was refused a Confederate Patent based on the fact that Read had already covered it by stating "...the cylinder may be fastened on by screws...to the body..." So was Read’s patent infringed upon?

In 1856, Dr. Read brought his invention to Robert Parker Parrott, superintendent of the West Point Foundry, located in Cold Spring, New York, where afterwards Parrott purchased from Read the sole right of manufacture of Read's projectile for the United States government. Major Alexander B. Dyer gave a good recommendation of the Read projectile after the trials made at Fortress Monroe. Parrott made, after numerous and costly trials, an improvement to the Read projectile in 1860. In 1861, Parrott patented his improvement on August 20, patent #33,100. Although Parrott gives Read credit for his invention Read accused him of an infringement of his patent #15,999. Parrott states in his patent "This invention consists in an improvement upon the elongated projectile for which Letters Patent of the United States were issued on the 28th day of October, 1856, to John B. Read."

Some collectors have trouble identifying the Read and Parrott projectile types due to the similar exterior characteristics of the early patterns that were both developed from the inventors employing each others ideas. The Read and Parrott projectiles were the two most common projectiles employed by both sides during the Civil War.

The projectile shown is Read’s drawings of his patent. The patented projectile was never manufactured during the Civil War and only a few test specimens are known. Frequently the projectile and the patent are quite different in appearance as is the case of Hotchkiss’s 1855 patent and the his projectile employed during the Civil War.

Located in the nose of the projectile is a percussion fuzing system

known as a West Point Type. This type of percussion fuze was developed, after many trials

and experiments, at West Point, New York. The fuze consists of a slider and anvil cap. The

slider supported a nipple and percussion cap and it rested in the cylindrical chamber

beneath the iron anvil cap. At the moment of impact with a target, the slider moved

rapidly forward striking the flat base of the anvil cap communicating fire from the

percussion cap to the projectile’s interior bursting charge. Read does not claim to

have invented this style of percussion fuze in his patent.

Read’s final statement in his patent is as follows:

"What I claim as my invention, and desire to secure by Letters Patent, is—

The attachment to elongated shot or shells of a cylinder or wrought-iron fastened to the body of the shot or shell by having its bottom or sides more or less embedded in the cast metal of which the shot may be composed, the cylinder to be attached to the butt of the shot or shell, and its sides to project beyond, being thinned down after a short bevel to such a degree as exactly to fit the bore of the gun when the charge is fired, so as to save windage in all case and impart rotation when rifle-grooves are employed." Click here to see an example of the above patented shell.

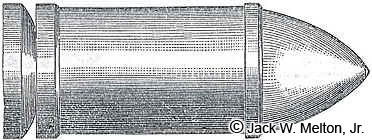

This is a drawing of Read's Safety

Groove. Note the space between the sabot and the bottom bearing

surface ring. When the projectile was fired the propellant charge

forced the copper sabot into the grooves of the cannon and this action

pushed the sabot forward. Thus, the groove allowed for the expansion

and was designed to help prevent chipping of the iron projectile sides.

To see more projectiles that were manufactured after Read's idea click here.